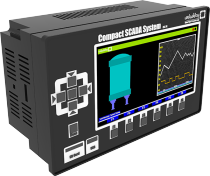

Compact SCADA

Introduction:

The PAC consists of a display, monitor and transmitter of information is in one place and Data acquisition and Controller integrated HMI and HMI functionality independent of the traditional view of the Controller and remove existing problems in the relationship between these two parts is high.

This combination, controls more efficient and easier maintenance safer, less expensive and potential benefits of reduced wiring complexity, more efficient operation system provides medium to large.

According to the HMI system integrity processor and a much higher speed than the processor is capable discrete programmable HMI, connectivity has created much better and faster for users.

As well as integration with HMI and PLC's wide range of industrial control panels and panels can be as simple as possible. The better the performance, the possibility of error and speed much faster implementation for large systems, especially in large industrial network provides.

Features & Benefits:

General :

- Control systems PAC, signal processors, displays and a wide range of input / output and integrated industrial network

- SOC powerful processor capable of processing and parallel processing to speed 200MHz

Display:

- 7-inch full-color touch screen Touch screen systems

- Drawing capabilities of graph

operating system :

- Real-time control with Tick, 0.1ms

- Loaded applications based on Application

- The ability to control up to 16 axis motion control (motion control)

- The ability to control up to 6,500 nodes

- FAT via SD slot and USB

- Equipped with up to four channels LBus port compatible with Modbus and RTU protocol with the ability to function at high speed

- The port isolation LBus

Bus:

- Ethernet port for Full Duplex, 100mps to connect to Ethernet or Fieldbus

- Equipped with high-precision analog ports (0.001 percent) for reading information panels and weight measurements.

- Equipped with four-channel input circuit 4 to 20 mA or HART

- Equipped with 16 digital inputs or high-speed type isolated

- Equipped with 16 digital output of high current (40ma) or high speed

- Fieldbus network port is equipped with a GSM-compatible processing MBus protocol and CANopen Can function for high-speed Fieldbus systems

Power supply :

- Equipped with powerful internal power supply

- It supports two parallel power supply input to the controller for safety Balatrtvan

- Protection against surge current, input noise and sudden changes in power supply up to 3 times the operating voltage power supply with automatic internal thermal fuse

Software:

- Meet 3 -IEC61131

- Support from powerful internal FB

- Functionality equivalent to 320 thousand lines Ladder

- Sixteen parallel application support

- All variables for online visibility program of the Central Bus

- Sixteen-axis motion control capabilities through the MBus

- Support 64 PID Controller for online

- Object-oriented programming language Python

- Floating numbers when calculating calculator with less than 1Us

- Local application management capabilities through the Central Bus

- Update on time of less than 10ms Central Bus

- The possibility of creating a specific FB and ultrafast ++ C based language

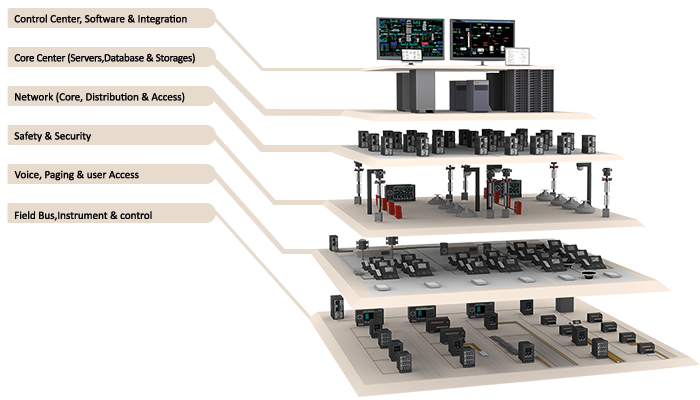

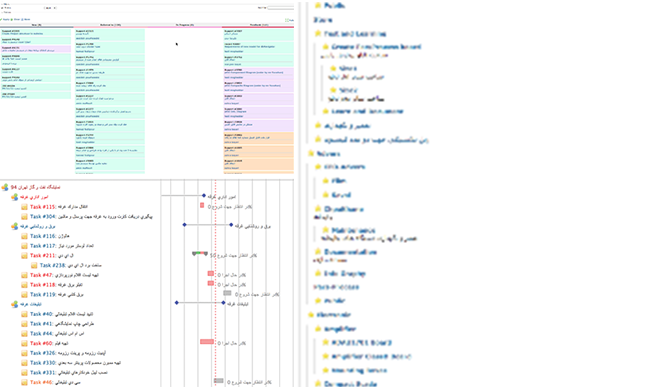

Block Diagram

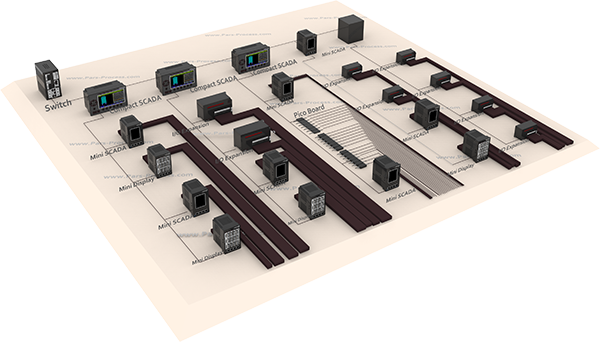

Example 1: BLOCK Diagram of connections in a large system

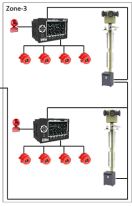

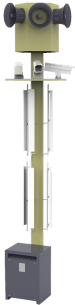

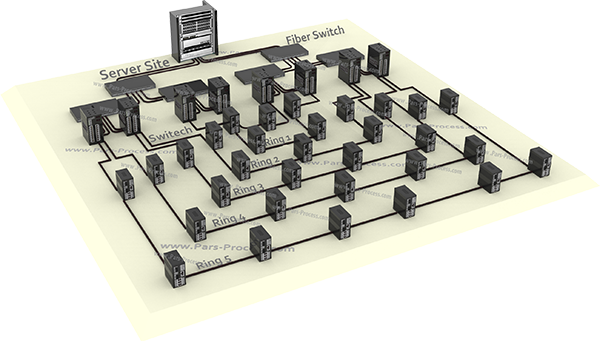

Example 2: surveillance and fire alarm system with the possibility of remote reading:

Standards:

- IEC 61496 Safety f., e.g., Light curtains

- IEC 61131-6 Safety for PLC

- IEC 61800-5-2 Safety functions for drives

- ISO 10218-1 Safety requirements for robots

- IEC 61784-4 Security (profile-specific)

- IEC 62443 Security (common part)

- IEC 61784-5 Installation guide (profile-specific)

- IEC 61918 Installation guide (common part)

- IEC 61000-2-1 Methodology EMC+FS

- IEC 61326-1-3

- IEC 61000-6-7 Test EMC+FS

- IEC 61508 Functional safety (FS) (basic standard)

- ISO 12000-1 and ISO 14121 Safety of Machinery-Principles for design and risk assessment

- Design of safety-related electrical, electronic and Programmable electronic control systems (SRECS) For machinery

- STL based Pl based

- IEC 60204-1 Safety of electrical equipment

- US: NFPA 79 (2006)

- ISO 13849-1,-2 Safety-related parts of machinery (SRPCS) Nonelectrical